Another piece I was commissioned to do. This is a J.C. Higgins Model 662 pocket knife. It was originally sold by Sears between 1948 and 1962. This one seems to have withstood the test of time while still getting plenty of use. I do not have many photos of it before, however it was originally leather handled. Through the 50 some odd years of use the leather had become hard and brittle and fell off. Since this was before stainless steel was cheap and common on knives it had begun to rust under the handle and had an overall mild pitting.

While this may not have been the most expensive knife of its time I find it very cool. If only it could tell its stories. I'm glad I was given the opportunity to give it new life. I hope it's still in use in another 50 years.

During disasembly the pommel on the end split.... Such is life, it was super thin anyways. I made a new pommel from billet aluminum. The wood is Franquette English walnut finished with a homebrew mix of tung oil and alkanet root. The wood is one piece one single piece and was hand inlet for accuracy. The front gaurd is original, it had this cool patina to it I didn't want to mess up too much.

I really wish I had a chance to get better photos before I had to give it to the owner, but he was pleased to have it before a weekend of fishing.

Drew Builds Stuff

Monday, February 27, 2012

Comissioned work

I did this ring for a friend to give away as a gift. It is made from Black and White ebony grown in Laos. It exhibits many qualities of the other ebonies being very strong, hard and able to take high polish. Finished with 5 coats of cyanoacrilate and polished. Size 6 I believe, I just asked the individual it was for for an inside dimension.

Wednesday, January 25, 2012

Franquette walnut and alkanet root

A bit of a teaser for a project. I'll go into this more as it is getting close to done.

For now, a bit of viewing pleasure. Exhibition grade Franquette variety walnut and a jar of my home made all natural Alkanet root and Linseed stain.

For now, a bit of viewing pleasure. Exhibition grade Franquette variety walnut and a jar of my home made all natural Alkanet root and Linseed stain.

Rust bluing

As my fascination with firearms continues its time I learned something new.

Rust bluing is a process that is actually fairly old. It involves polishing the parts to a desired finish, then applying a weak acid solution to evenly rust the parts in a very thin layer. The parts are then either boiled or steamed until the rust is converted into a more stable oxidation state. After cooling the majority of the black iron oxide is removed by either a very fine stainless brush, or steel wool.

This process is somewhat labor intensive, however I am quite pleased with the results thus far. I will probably use this on many projects to come.

For those curious, this is converting Fe2O3 into Fe3O4.

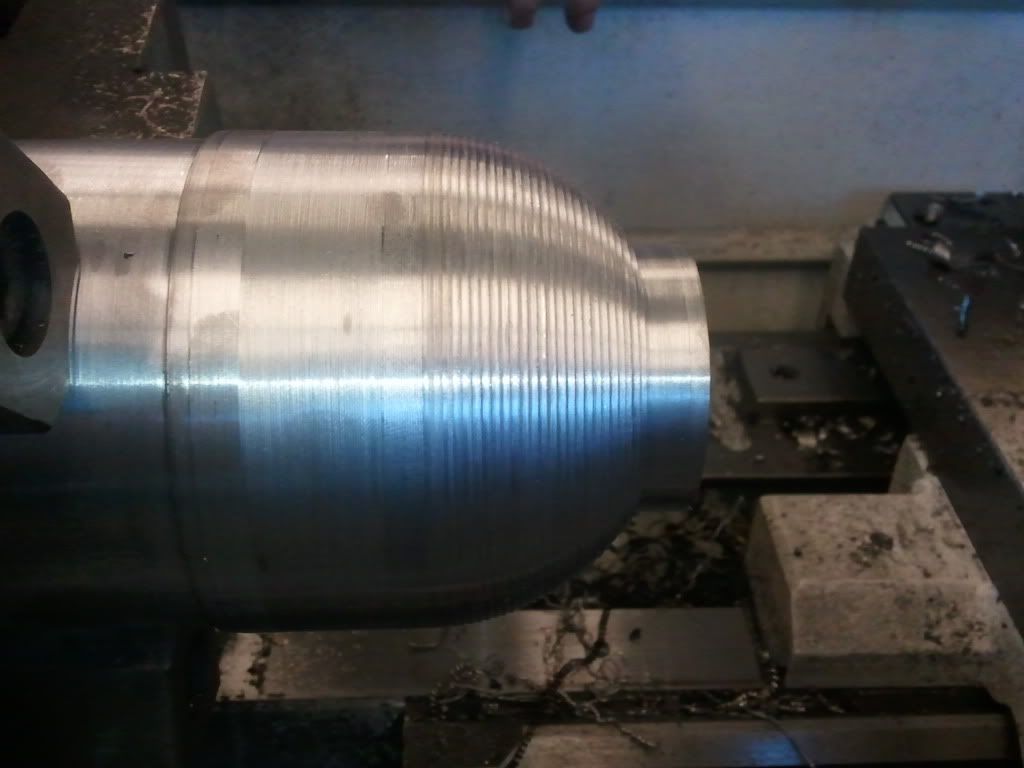

Please note, in this first picture I overlapped too much causing it to "copper" which is not desirable, it still looks cool. 2nd item is a part for my lathe that I machined to hold large items on both sides of the head stock.

Rust bluing is a process that is actually fairly old. It involves polishing the parts to a desired finish, then applying a weak acid solution to evenly rust the parts in a very thin layer. The parts are then either boiled or steamed until the rust is converted into a more stable oxidation state. After cooling the majority of the black iron oxide is removed by either a very fine stainless brush, or steel wool.

This process is somewhat labor intensive, however I am quite pleased with the results thus far. I will probably use this on many projects to come.

For those curious, this is converting Fe2O3 into Fe3O4.

Please note, in this first picture I overlapped too much causing it to "copper" which is not desirable, it still looks cool. 2nd item is a part for my lathe that I machined to hold large items on both sides of the head stock.

Thursday, January 19, 2012

Christmas stuff

Here's a few projects I did for Christmas. I can't believe I crammed all of this into about 6 weeks.

A bracelet I made for a co-worker to give to his daughter. This is made from Amboyna burl. Cut for a flame pattern. Unfortunately I did not take any photos after final polish.

A bracelet I made for my mother from Redwood root burl.

Wine bottle stoppers I made. The red ones are Cocobolo and I gave them to my stepmother. The other one is Black and White Ebony and was given to a friend back in Dallas.

This is a knife I made for my Father with some of the Redwood root burl. I apologize for the lens flare but it was the only way the grain showed up. Once again I failed to get a photo after final polish.

A bracelet I made for a co-worker to give to his daughter. This is made from Amboyna burl. Cut for a flame pattern. Unfortunately I did not take any photos after final polish.

A bracelet I made for my mother from Redwood root burl.

Wine bottle stoppers I made. The red ones are Cocobolo and I gave them to my stepmother. The other one is Black and White Ebony and was given to a friend back in Dallas.

This is a knife I made for my Father with some of the Redwood root burl. I apologize for the lens flare but it was the only way the grain showed up. Once again I failed to get a photo after final polish.

Grip checkering vice.

Got the idea for this looking at engraving vices. I think it turned out pretty nice, I'll machine an engraving vice later from larger material with a bearing to make it easier to work on larger pieces.

The base was cut from Claro (Paradox) Walnut, unfortunately it was still wet when cut and warped too much to be usable when it dried.. I'll pick up a piece of Franquette walnut that's already dried and redo the base soon. This will be good practice for practicing the traditional Alkanet Root stain done on fine English firearms.

1018CR mild steel. 3.875" diameter steel ball with a 2" pad for the vice jaws to mount to. Tapped for 5/8-16 stud. Cut on a Birmingham YCL-2280. I think I had about 2hrs machine time on this, excluding polishing.

The base was cut from Claro (Paradox) Walnut, unfortunately it was still wet when cut and warped too much to be usable when it dried.. I'll pick up a piece of Franquette walnut that's already dried and redo the base soon. This will be good practice for practicing the traditional Alkanet Root stain done on fine English firearms.

1018CR mild steel. 3.875" diameter steel ball with a 2" pad for the vice jaws to mount to. Tapped for 5/8-16 stud. Cut on a Birmingham YCL-2280. I think I had about 2hrs machine time on this, excluding polishing.

Yildiz SPZ ME project: Part 1

Alright y'all here's the start of my trap shotgun. I went to Academy Sports right before I left Texas and spent a considerable amount of time with one of their helpful store clerks digging through some of their Yildiz Shotguns. These are sold exclusively through them and available no where else. Since Academy is regional, I knew I had to get one then.

What I was looking for was something special. While I knew all of these would be more than decent enough to get me into the sport, I wanted something I can tinker with. After looking at 2 we finally opened up the box I went home with. A Yildiz SPZ ME 12ga. over/under with a 3" chamber and decent looking wood. After looking it over in the store I came to the conclusion that this particular gun looked like it needed some finish work and had somehow got through the quality assurance. Perfect, I'm not able to machine actions or barrels nor do I have the correct licensing to do so.

So what major things does this shotgun really need?

Keep in mind, others sold by them did not need most of this, I was looking for a project.

First things first, the barrels lock up too tight right now, a quick check with a bit of flame inletting and I can see where I'd like to remove the slightest amount of material to get a better contact patch with the receiver and to get the unlocking lever to return to 100% center. As of right now, 100% spotless clean and lightly oiled, with the barrels closed, the unlocking lever is 3-4 degrees off from fully locked. Some very light polishing of the breech face should solve this problem.

Next thing I noticed was how tight the sides of the barrel fit with the receiver. I have to use about 5lbs force near the middle of the barrels to open the chamber. After shooting 100+ rds shooting trap the last thing I want to do is grab a hot barrel. I will lightly polish the barrel and if needed the receiver to reduce this effort to a flick of the shotgun to open the chamber. All of them seemed tight but this was exceptionally tight.

The triggers aren't too bad, maybe an 1/8th or so of take-up and a clean crisp break probably around 5 lbs. I don't think I'll do anything with this.

The wood needed a bit of work. It looked like some very nice walnut. These guns are Turkish so I assume it is locally grown. Some of their higher end models may have the desirable marble cake black streaking, however this did not. It does have a little bit of "curl" or "fiddleback" and looks to have been part of a crotch. This is some of the nicest wood I've seen on a firearm of this price. It came matte and looked like it had a single coat of oil on it. I threw a couple coats of Tru-Oil on it to protect the wood from myself and it shined up quite a bit.

The checkering is a bit flat in spots. I'll bring up the points and re-oil those areas next.

What I was looking for was something special. While I knew all of these would be more than decent enough to get me into the sport, I wanted something I can tinker with. After looking at 2 we finally opened up the box I went home with. A Yildiz SPZ ME 12ga. over/under with a 3" chamber and decent looking wood. After looking it over in the store I came to the conclusion that this particular gun looked like it needed some finish work and had somehow got through the quality assurance. Perfect, I'm not able to machine actions or barrels nor do I have the correct licensing to do so.

So what major things does this shotgun really need?

Keep in mind, others sold by them did not need most of this, I was looking for a project.

First things first, the barrels lock up too tight right now, a quick check with a bit of flame inletting and I can see where I'd like to remove the slightest amount of material to get a better contact patch with the receiver and to get the unlocking lever to return to 100% center. As of right now, 100% spotless clean and lightly oiled, with the barrels closed, the unlocking lever is 3-4 degrees off from fully locked. Some very light polishing of the breech face should solve this problem.

Next thing I noticed was how tight the sides of the barrel fit with the receiver. I have to use about 5lbs force near the middle of the barrels to open the chamber. After shooting 100+ rds shooting trap the last thing I want to do is grab a hot barrel. I will lightly polish the barrel and if needed the receiver to reduce this effort to a flick of the shotgun to open the chamber. All of them seemed tight but this was exceptionally tight.

The triggers aren't too bad, maybe an 1/8th or so of take-up and a clean crisp break probably around 5 lbs. I don't think I'll do anything with this.

The wood needed a bit of work. It looked like some very nice walnut. These guns are Turkish so I assume it is locally grown. Some of their higher end models may have the desirable marble cake black streaking, however this did not. It does have a little bit of "curl" or "fiddleback" and looks to have been part of a crotch. This is some of the nicest wood I've seen on a firearm of this price. It came matte and looked like it had a single coat of oil on it. I threw a couple coats of Tru-Oil on it to protect the wood from myself and it shined up quite a bit.

The checkering is a bit flat in spots. I'll bring up the points and re-oil those areas next.

Subscribe to:

Posts (Atom)